PRODUCTS

TS SERIES TOOLING STATION OPTIONS

Remco's Tooling stations are completely customized to meet your production needs. Let us know the specifications you require:

- Maximum Diameter Capacity - Maximum Weight Capacity - Number of Tooling Carriages (up to two) - Your Plant Voltage - The Option(s) you desire below

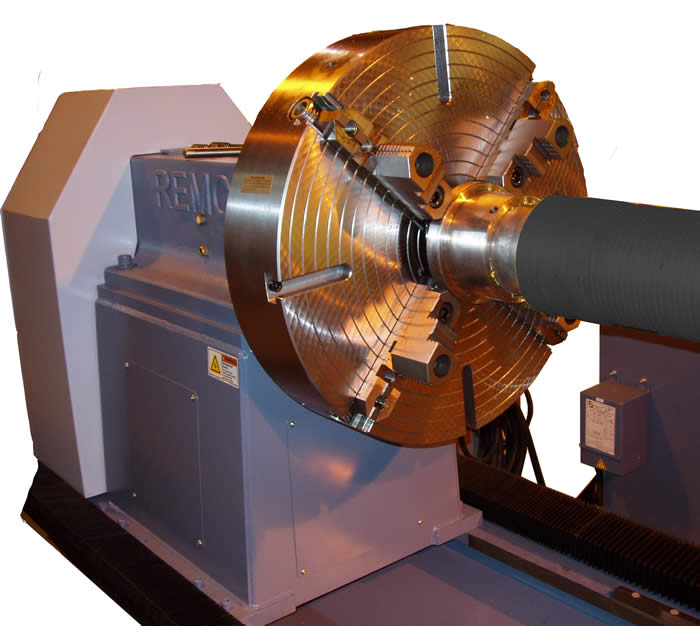

Tool Post.- (1) 1” height adjustable tool post. (Photo 1) Check Size Upgrades- Up to 25" Chuck Dual Spin Stations (Photo 2)Put your SS Spin Station or TS Tooling Station Tailstock to Tailstock for flexibility and capacity. Utilize this as a double spin station with the ability to hold and build or tool two packers, rollers or parts...or....slide your tailstocks to one end and build one long roller or packer. (Photo 2) Local Control for Dual Spin Stations (Photo 3)Give your operator control of one (SS) Spin Station or (TS) Tooling Station while Strip Building Rubber on the other. Remco builds two different Strip Builder Extrusion systems, the (TSB) Thermoset Strip Builder for Rubber and the (TPB) Thermoplastic Strip Builder. If your polymer is engineered for extrusion, Remco's Strip Builders or let off systems can build it. Pneumatic QuillD1 Spindle(s)

Tailstock with Rotating Spindle & ChuckMedium Speed Grinding Head (Photo 5)The MSG 1200 Series Grinding Head can be adapted to Remco's Tooling Station to produce precision ground finishes.

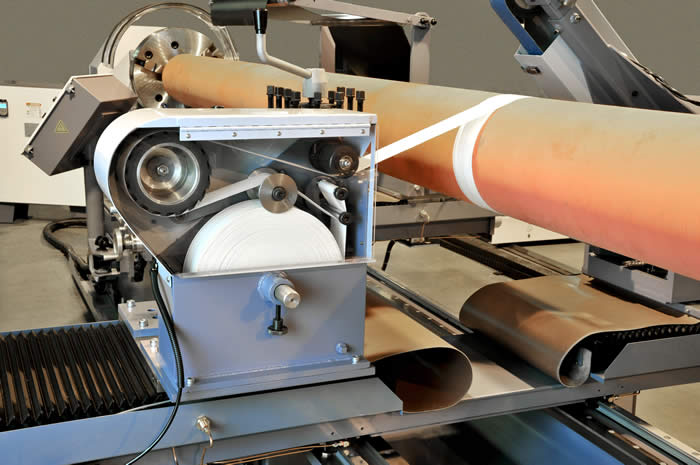

High Speed Belt Grinding Head (Photo 6)The HSG 1000 Series Grinding Head can be adapted to Remco's Tooling Station to produce precision ground finishes.

BGA Belt Grinder Attachment (Photo 7)The BGA 160 (Belt Grinding Attachment) was built primarlily for preparing metal surfaces for bonding elastomers. BGA 160

BGA 275

BGA 290

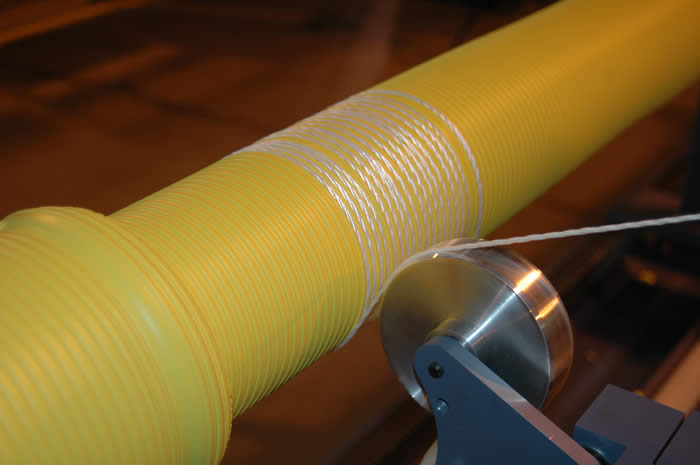

Material Reinforcement Applicator

|

click to play video

Photo 1- Toolpost

Photo 2- Dual Tooling Station on Strip Builder

Photo3- Local Control for Dual Spin Stations

Photo 4- TS Upgraded Chuck with Rotating Spindle

Photo 5- (MSG) Medium Speed Grinding Head

Photo - 6 (HSG) High Speed Grinding Head

Photo - 7 (BGA) Belt Grinding Attachment

Photo - 8 Material Reinforcement Applicator

Photo - 9 Tape Wrap Attachment |